In-Depth: Does Great Movement Finishing Mean A Great Watch?

A seemingly simple question has a very complicated answer.

A few weeks ago, we published an in-depth look at one of the new watches from Montblanc. The watch in question was the Heritage Manufacture Pulsograph, which uses a movement made at the Institut Minerva de Recherche en Haute Horlogerie in Villeret. As most enthusiasts will probably already know, this is the facility that was home to the Minerva watch company, which in the last 20 years has had a couple of changes of ownership, as well as direction, and which now produces hand-finished movements for Montblanc watches.

It is always interesting to see the reactions to the Montblanc Minerva pieces specifically, because they raise some interesting questions. Leaving aside the whole question of how the company has evolved since being acquired by the Richemont Group in 2006 (and how it evolved after the Frey family sold it in 2000), the reaction to the quality of the Minerva movements from enthusiasts is often very positive, as they represent well-finished examples of very traditional, classic watchmaking in a very typical high-end Swiss idiom.

However, this particular aspect of watchmaking is not one with universal appeal. On the one hand, it would be surprising if it did have universal appeal, as tastes differ. On the other hand, however, those who do not find themselves particularly interested in the craft of movement finishing, and who regard modern watchmaking as an affair which ought to emphasize innovation in engineering and precision in performance, may find finishing superfluous at best. To them, it might seem to be a relic of a time in which, having no real innovations to present, watchmakers idled away the hours by giving movements a jewel-like appearance (to paraphrase a famous remark made by George Daniels, who himself preferred a more sober and less obviously dazzling appearance for his own movements). In the comments to the Heritage Manufacture Pulsograph, there were several such dissenting views expressed, and one HODINKEE Community member, danlazop, wrote:

“If I may ask: I have read many times that the true distinction of haute horlogerie is the craft of the traditional finishing, which always troubles my modernist inclined mind, since it seems to put decoration above engineering and overall design. In my mind, a beautifully crafted mediocre design is still mediocre, although I can see the merits of the effort. Since I’m no expert in movement engineering, do mediocre movement engineering but beautifully finished still pass as haute horlogerie, or this doesn’t exist?”

This is such a very big question that I hesitated at first to try to give an answer at all. It would require a book, and a big one at that. However, it is such an interesting question that it seemed a shame to me to chicken out and not try to answer, at least in broad strokes. So, here goes.

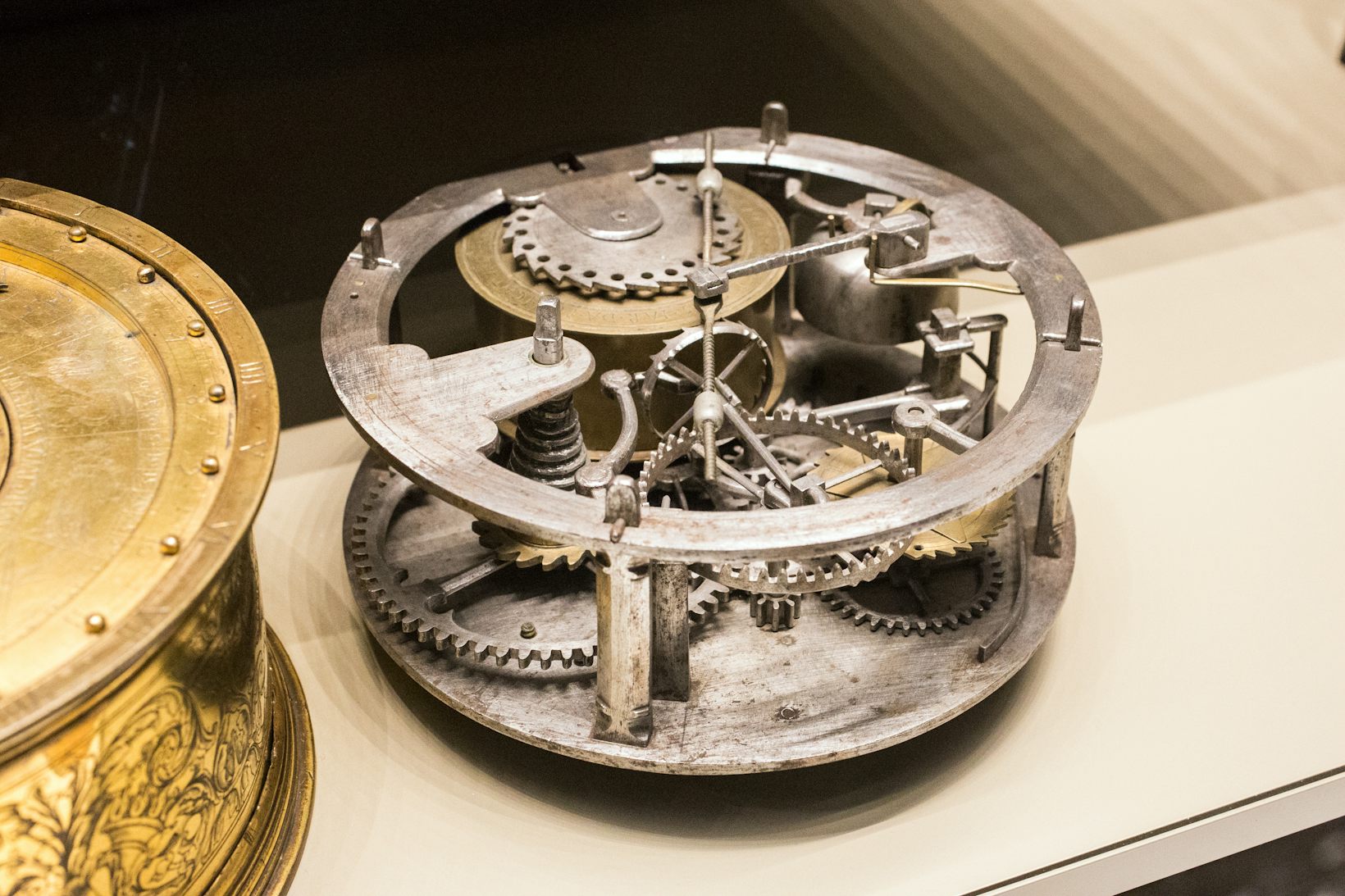

The subject of movement decoration has to be looked at in a larger context, as the techniques do not exist in a vacuum. Rather, they are the result of the varying roles watches have played over the centuries and how the technology of timekeeping has developed. Movement decoration is something that has continued to evolve over the entire history of watchmaking. Many early movements – this is going back to the earliest table clocks, which gradually evolved into watches as they got smaller – had iron movements, and while they could have very elaborately decorative cases, the movements tended to be more or less completely unadorned.

Things gradually began to change as clocks became smaller and smaller, and transitioned to becoming watches. For one thing, iron (which had also been used for early tower clock movements) was gradually replaced by brass, which was usually given a gilt coating in order to discourage corrosion. The first generation of real, portable watches featured movements given some degree of decoration almost immediately, and in particular, the balance cocks tended to be elaborately engraved.

It is certainly not true that at any time, movement decoration was ubiquitous in horology. However, as a rule, watchmaking seems to have tended to encourage movement decoration to a much greater degree than clockmaking where, however ornate the dial, case, and hands might be, the movements tended to be largely unadorned.

Watch movements, however, during the sixteenth and seventeenth centuries, seemed to become increasingly ornate. This is probably at least partly due to the fact that watches were not especially accurate. The role of accurate timekeeping was restricted to clocks, sundials, and the observation of astronomical transits. While watches were essentially inessential toys for the wealthy, there was every reason to give them the florid ornamentation for which so many early watches are notable. As most movements could be at least partially viewed by the owner, thanks to hinged casebacks and covers, watchmakers exerted themselves to ornament them. It is interesting, however, that one of the first truly precise pocket watches, John Harrison’s H4 (which is arguably a portable clock rather than a watch, and which was meant to be kept on a cushion when in use, not worn in a pocket) had incredibly elaborate engraving on the movement – so much so that it has been speculated that Harrison gave the watch such lavish engraving in order to make it harder for competitors to discern the technical details.

An interesting parallel can be found in a related discipline, which is the making of firearms. For anyone whose familiarity with them is confined to the machined steel and synthetics which are the stock-in-trade of modern guns, the degree to which firearms were decorated in the past can come as something of a shock. Like watches, guns were for much of their history all basically craft-produced one-offs, until muskets started to be mass-produced in the 1820s thanks to the invention of milling machines that could make interchangeable parts. The Arms And Armor hall at the Metropolitan Museum Of Art gives an instructive look at just how florid the decoration of fine firearms could be and reflects the same impulse that led watchmakers to create highly ornamented watches. If you are creating craft-made objects for wealthy clients, there is an expectation that they will look the part, not just function well.

This first phase of movement decoration began to change thanks to two occurrences. The first was the application of the balance spring to the balance. The second was the development of more precise alternatives to the verge escapement – first the cylinder, and then the lever escapement. As the 18th century began, watches capable of keeping time to within a minute a day, or better, began to be developed, and as watches became more precise mechanically, greater and greater effort was expended on making each part to as high a degree of precision as possible. Breguet’s work is a case in point. His movements to the modern eye can look very beautiful and indeed, even artistic, but this is not so much due to a desire to create a decorative effect per se as it is the natural result of years of craftsman’s experience and general good workshop practices.

The Breguet No. 1176 is an interesting case in point. The watch was made for a prominent Polish nobleman, Count Stanislaus Potocki, and was one of what Breguet called his garde temps watches – generally, extremely high-grade timepieces made for clients with an interest in the pursuit of chronometry for its own sake. Certainly, the movement is beautiful, but it is in contrast to earlier watches in which precision in timekeeping could not be expected and which were often ornamented with a view to making them more entertaining toys to look at (like almost any generalization you care to make about watchmaking, there are exceptions, but I think the assertion is reasonably valid). The movement is very beautiful, assuming you are moved to call a hand-made high precision, high-craft machine beautiful, but the various contrasting finishes are the result of the pursuit of durability, longevity, and precision. Fire-gilding and the bluing and polishing of steel parts all help retard corrosion, and the beautiful symmetry of the movement, and the visually pleasing dimensions and form of the tourbillon, are the consequence of the fact that if the potential exists to make a precise timekeeper, what might in the past have been a reasonable degree of imprecision can no longer be tolerated. Advances in precision in the oscillator mean that imprecision elsewhere, which would not have been evident in one of the crude early watches of the 16th century, must be eliminated.

Does this mean that Breguet did not consider the visual effect of his movements? Given the great sensitivity which he showed to visual harmony and compositional balance in his dials, I find it difficult not to believe that he was, at least to some degree, bringing the same sensibility to his movements (and after all, the position of the various wheels and other components of the movement determine what you can do on the dial side). Perhaps one of the clearest indications, however, that he was not immune to the visual fascination of precision mechanics was the Breguet No. 160, which is better known to watch enthusiasts as the “Marie Antoinette” Breguet. The original resides in the Meyer Museum Of Islamic Art in Jerusalem, but Breguet has created an exact duplicate of it – No. 1160, with which we went Hands-On in 2017 – and it is perhaps one of the most astonishing examples of beauty in a mechanism you could ever hope to see.

To say that the finish here is merely decorative or that it is merely the outcome of the pursuit of precision is, I think, to create a false dichotomy and one which I very much doubt existed in the minds of those responsible for making it. This is, to me, one of the most important distinctions to make in looking at movement finishing.

One of the interesting things about being a watch writer with an interest in technical and historical context nowadays is that there is a non-zero chance that Walt Odets, who basically invented the genre of the technical watch review on Timezone.com in the early 2000s, got there before you did. So it is with movement finishing, and I recommend his series on the subject very highly (as I do everything he ever wrote on horology, no exceptions). I think one of his comments in that series is especially apropos at this point:

“On the subject of finish and durability, only a single obvious fact need be pointed to. If every part of a movement has a function, it is also true that almost every part works against another part. The finish of these working surfaces has everything to do with how long they will last. While poorly finished surfaces may be partially compensated for in the short term with good (and, sometimes, excessive) lubrication, in the long term they will show themselves with excessive wear, and, worse yet, by depositing the particulate products of that wear in other working parts.”

With that in mind, we can take a closer look at how movement finishing evolved as the age of high precision portable timekeeping dawned and progressed, and how it continued to evolve in the wristwatch.

This is a pocket watch tourbillon, made by Jaeger-LeCoultre in 1946, and though it’s not a wristwatch per se, it’s a great example on a large canvas of what movement finishing in the top tier looked like, mid-20th century. This is largely a hand-made watch, and at this point, there is still not really a hard and fast distinction between functional and decorative finish. It’s a watch that was made as part of a run of 26, by JLC, to compete in the observatory trials. The impression you get is that the finish is not so much an attempt to create anything decorative only, but rather that it is the natural end product of the hand-made nature of the watch and of the desire on the part of its makers to ensure longevity in operation, as well as the highest possible degree of precision.

Nonetheless, the full vocabulary of modern, high-end watch finishing is present, including black-polished steelwork, Geneva stripes, polished screws and mirror-polished countersinks, and so on. You don’t so much get an impression of something that has been decorated as you do of a machine built with the utmost care, by hand, to perform a very singular and very demanding task.

Now, this is where things start to get interesting for the wristwatch enthusiast. The pocket watch you see here has no lower-end counterpart – it’s not as if there’s a mass-produced base caliber, whose mechanical quality can be evaluated separately from the movement. However, by the mid-20th century, mass production of watch movements in Switzerland had reached a point where a couple of interesting things were starting to happen. The first is that milling of parts had started to reach a point where hand-finishing and tuning were becoming less and less necessary for a watch movement to function. The second was that there were now instances of a movement which might have a production run in the tens of thousands (or more) showing up with dramatically different levels of execution. One of the most dramatic examples is the Lemania CH 27.

This particular movement was developed in the 1940s and was the basis for the Lemania 2310, which Omega used as the caliber 321 in the Speedmaster. It was also, and quite famously, used as the basis for movements from other makers, including Patek Philippe and Vacheron Constantin; the latter used it as the basis for the caliber 1142, which is found in, among other places, the Cornes de Vache chronographs.

When we finally got a chance to get the newly re-introduced Speedmaster in for photography, we also took the opportunity to put it next to a Vacheron caliber 1142, and the similarities and differences are quite dramatic.

There are immediately obvious aesthetic and technical differences between the two movements, and it’s instructive to note both, as a way of both understanding movement finishing and as a way of understanding the relationship between finish and functionality. Both of these iterations of the movement are excellent mechanically, in their respective positions, however, the caliber 321 is an example of very high-quality execution at what, in its original form, was intended to exist at a relatively affordable price point (the re-introduction is of necessity more expensive thanks to quite small production numbers, and the artisanal approach Omega takes to assembly and fine-tuning performance). The 1142, on the other hand, is clearly intended for a different audience.

Now, for me, the takeaway here is that in neither case are you starting with a movement that is qualitatively sitting at the lower or even the middle part of the horological spectrum. Generally speaking, you don’t see this level of finish lavished on a movement which, without it, is of middling or poor quality. Historically and, to a certain extent, right down to the present, high-grade finish is deployed on high-grade movements, and the overall better quality in finish is often wedded to better fine adjustment chronometrically speaking, as well as the potential for greater resistance to wear. Better finishing on working surfaces such as gear teeth, pinion leaves, levers and reset hammers, and so on, often means less friction and a better chance of mechanical longevity.

The question, “does great finishing mean a great movement,” depends, in turn, a great deal on what you mean by “great movement.” The most technically advanced movements being made today in meaningful industrial numbers, such as (to pick just a few examples) Omega’s co-axial calibers, Rolex movements, and more recently, Seiko’s new Grand Seiko Hi-Beat movement, generally are not the beneficiaries of leisurely traditional hand finishing techniques. These are very time-consuming and add considerably to the cost of the watch as they must be executed by trained hands, and moreover, it has for some time been possible to produce very good, even immaculate, industrial finishing on watch movements without recourse to pithwood sticks and hand-held burnishing tools, and the like.

Such techniques would, if used on movements such as the Omega caliber 9905, represent considerable additional expense. In terms of the movement’s purpose – which is to provide, as much as possible, cutting-edge technical solutions to the problem of chronometry – it would not be added value and, indeed, would be something of a disconnect with the technical nature of the caliber. While the movement does exhibit very striking finishing on the visible surfaces, it does not represent the use of traditional manual craft techniques (which should not be expected at this price point) and could be largely dispensed with, without affecting the core functionality of the watch. In this instance, they exist as a connection to a tradition of movement finishing which was, in its inception, inextricably connected to the craft techniques necessary to make any watch at all (as well as, of course, to communicate to the owner the care that went into the design and execution of the watch overall).

Today, traditional hand-executed movement finishing is generally reserved for more exclusive calibers, and moreover those which represent the search for chronometric excellence through the use of traditional methods. The Montblanc chronograph which led to this story, for instance, does not have a silicon balance spring produced with techniques derived from the semiconductor industry. Instead, it has an alloy balance spring, which is given its overcoil by hand and which is pinned to the balance wheel by hand, using a method which is hundreds of years old. (In one of the greatest paradoxes in modern watchmaking, however, the technically advanced Spring Drive technology from Seiko is in the Credor Eichi watches, wedded to some of the best examples of traditional, hand-executed movement finishing in modern watchmaking.)

High-grade finish does not guarantee a technically cutting-edge movement. However, it is very seldom found, if at all, on movements which are produced in high volumes and which can be found in a wide ranger of watches, at least nowadays. I think an equally relevant question to consider, and a highly personal one, is to what degree it makes a watch more charming.

We do not, after all, all necessarily find the most technically advanced solution to a problem the most aesthetically attractive nor the most historically resonant, and technologically advanced mechanical horology can represent a disconnect with many intrinsically interesting craft techniques. Forming a balance spring overcoil by hand, adjusting ruby pallets by softening the shellac that fixes them in place, polishing pinion leaves with boxwood to a mirror finish in order to reduce frictional losses to a minimum, and poising a balance by hand are all relics of a way of keeping time which is completely inferior, from a purely technical standpoint, to relying on semiconductor technology to produce silicon balance springs and pallets or MEMS technology to produce skeletonized escape wheels.

But in watchmaking, much of the interest lies in how you do what you do, and, if you ask me, the sense of direct connection you feel when you look at and use a watch finished and adjusted by hand, using traditional techniques, is something worth cherishing and keeping alive.

Get More Articles Like This in Your Inbox

We're constantly creating great content like this. So, why not get it delivered directly to your inbox? By subscribing you agree to our Privacy Policy but you can unsubscribe at any time.