In-Depth: A Brief Exploration Of Funky Dive Watch Features

Three technologies that surprisingly made their way into dive watches.

Humankind’s quest to conquer the ocean has often resulted in technological innovations that blur the line between science fiction and reality. Exploring the ocean, from its crushing depths to its dangerous and ever-changing surface, presents a unique set of challenges that scientists have spent nearly a century trying to address. This sort of thinking has extended to horology, and plenty of innovation in dive watch design has occurred since the early ’50s when dive watches came into existence. Below, we’ll take a look at three specific innovations and how watch manufacturers have incorporated these technologies into their designs.

In 1962, Dr. Johannes A. Kylstra proved that mice could breathe – for a limited time, at least – underwater by filling their lungs with an oxygen-rich saline solution. The mice died shortly after being submerged, but it proved that it was, in theory, possible. The larger thinking behind the experiment was that humans potentially had the capacity to breathe liquid. Filling the lungs with liquid could theoretically address pressure-related dangers of deep diving.

Follow-up experiments proved that it was indeed possible for a human to breathe perfluorocarbon, a synthetic liquid that holds three times the amount of oxygen as human blood. This is the real-life technology behind the scene in The Abyss when Ed Harris puts on a liquid-filled dive suit in order to dive deep into the Mariana Trench without succumbing to the fatal effects of pressure at that depth.

And that same technology is found in some dive watches. The Sinn UX takes advantage of the fact that liquid is mostly incompressible by pressure at depth. Sinn calls it HYDRO technology, and the movement, dial, and hands sit in a clear bath of oil inside the case. By replacing the air that would usually exist in the case with oil, the watch achieves an impressive 12,000-meter depth rating. Of course this technology only works with quartz movements; the viscosity of the oil would put too much drag on the balance in a mechanical movement. I asked Jack Forster about the fine technical details of the problem, and this is what he said: “The fastest moving hand is the seconds hand and the hand only moves through 6º when it jumps (360º/60 seconds = 6º). The balance, on the other hand, has to swing 280-300º eight times a second in a modern watch (28,800 vph) and even the slightest additional friction can drop the balance amplitude dramatically so surrounding it in even very light oil is a non-starter.”

Atmospheric diving suits also take advantage of this technology. These self-contained hard suits often use oil-filled joint assemblies because the oil doesn’t compress at depth and allows the joint to articulate, not to mention staying properly lubricated. To learn more about the JIM suit, perhaps the most famous atmospheric diving suit, have a look at Justin Couture’s Watch Spotting story from yesterday. In it we hear from Cliff Newell, who was trained as a JIM suit operator.

Knowing how deep you are on a dive is as important as knowing how long you’ve been down, so it’s no surprise that manufacturers have tried incorporating the depth gauge into dive watch design. There are a number of complex ways to mechanically measure depth, but one design stands out for its extreme simplicity: the capillary depth gauge. It was a popular feature on dive watches during the ’60s and ’70s, but has since lost traction.

A small hole is drilled in the crystal that’s connected to a channel that runs around the circumference of the crystal. The channel is sealed at the end that’s not exposed to water. Printed on the dial, chapter ring, or bezel, are depth markings. It’s generally accepted that a capillary depth gauge is at its most accurate at depths of 10 meters and below, but the markings can reach 30 meters.

When a diver enters the ocean wearing the watch, water will enter the channel in the crystal. The air in the channel is then compressed as the diver travels deeper. A clearly distinct line forms where the air meets the water inside the channel and that line is read against the depth chart that’s printed on the dial or chapter ring.

Based on Boyle’s Law, the water will take up half of the channel at 10 meters, and roughly ⅔ of the channel at 20 meters. From 20 meters to 100 meters is where the gauge starts to get a little dicey, however. It’s difficult to read at those depths and the calibration is such that it’s hard to pinpoint accuracy, and this is most likely why modern dive watches don’t boast this funky feature.

During the early days of diving, divers relied on physical decompression tables to plan their dive, track their dive, and modify their dive if conditions necessitated it. Some of the inputs needed to make those calculations are time underwater, bottom time, and surface interval time.

The humble dive watch bezel was a vital tool in a diver’s kit. Back then the malfunction of this simple device truly could have been a matter of life or death.

In order to make sure the bezel didn’t inadvertently get knocked, manufacturers started to come up with technologies to “lock” the bezel in place and prevent it from turning if a locking mechanism wasn’t disengaged first. In other words, the bezel-locking mechanism made diving much safer.

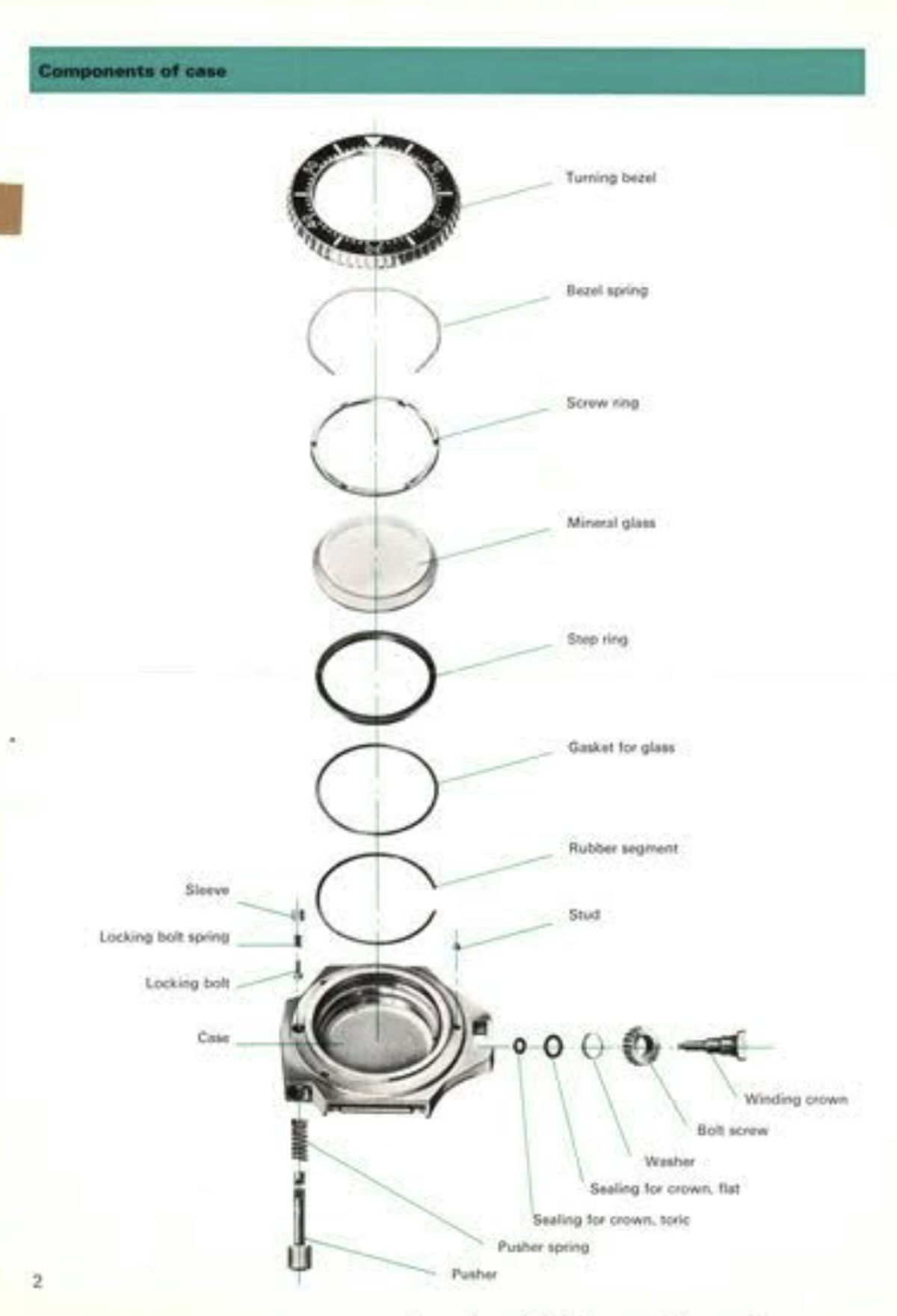

The most popular example of a bezel-locking mechanism is featured on the Omega Ploprof. The small button on the right side of the case is depressed in order for the bezel to turn freely. An internal locking bolt keeps the bezel in place when the button is resting. The mechanism is contained in the protrusion on the right side of the case, creating the signature shape of the Ploprof, but other manufacturers have created systems much more streamlined.

The Squale Tiger, released in 1988, features a similar bezel-locking mechanism integrated into the six o’clock lug. The bezel, when unlocked, spins freely in both directions. While both the aforementioned examples use a button-based locking system, Tudor developed a prototype for the US Navy that used a “claw” mechanism with teeth that locked the bezel in place from the 12 o’clock position. That prototype emerged decades later as the modern Tudor Black Bay P01.

Get More Articles Like This in Your Inbox

We're constantly creating great content like this. So, why not get it delivered directly to your inbox? By subscribing you agree to our Privacy Policy but you can unsubscribe at any time.