In-Depth: Everything You Always Wanted to Know About The A. Lange & Söhne Double Split And Triple Split* (*But Were Afraid to Ask)

How many splits does it take to get to the center of an A. Lange & Söhne rattrapante chronograph?

Originally published by on HODINKEE, September 22nd 2021

In the whole wide world, there are very few – if any – watchmakers more associated with the split-seconds chronograph today than A. Lange & Söhne. And that bond is so strong because of the Double Split and the Triple Split.

The Double Split measures elapsed split time in both seconds and minutes; the Triple Split, then, measures elapsed split time in seconds, minutes, and hours. Watchmaking has yet to go further – and it’s hard to imagine there’s much further to go. If you’re at the point where you can’t tell when a day has passed you by, even a six-figure wristwatch won’t save you.

Both the Double Split, in 2004, and the Triple Split, in 2018, were groundbreaking introductions (which also incorporate a flyback mechanism, for those of you keeping score at home). No watchmaker had dared introduce a chronograph that went beyond splitting seconds before A. Lange & Söhne revealed the Double Split, and no one has sought to challenge the company’s supremacy in the field since.

But as we learned with our recent deep-dive into the Calibre L101.2 inside the 1815 Rattrapante Honeygold Limited Edition, there are many ways one can go about constructing a split-seconds chronograph. And as I teased at the end of that article, today we’re going to take a look inside how these superstar split-seconds chronographs work, with a helping hand from our friend Anthony de Haas, the director of product development at A. Lange & Söhne.

The Double Split

The movement architecture of the Double Split is based around the work A. Lange & Söhne did in the Datograph. The Datograph was Lange’s first in-house chronograph movement, which, when introduced in 1999 – to put it ever so bluntly – slapped the Swiss watch industry in the face. (No need to name names, but every time I think about the Datograph’s debut, I can’t help but imagine that the turn of the century must have been a fraught time to be a watchmaker at certain manufacturers in Geneva.)

After the Datograph, A. Lange & Söhne didn’t rest on its laurels. By 2001, the company was already hard at work on what would become the Double Split, the first-ever double rattrapante chronograph. And remember, at this point in time, the Datograph was the first new in-house chronograph movement anyone had seen in years. Patek Philippe wouldn’t introduce their first in-house chronograph caliber until 2005; Vacheron Constantin, 2016; Audemars Piguet? 2019.

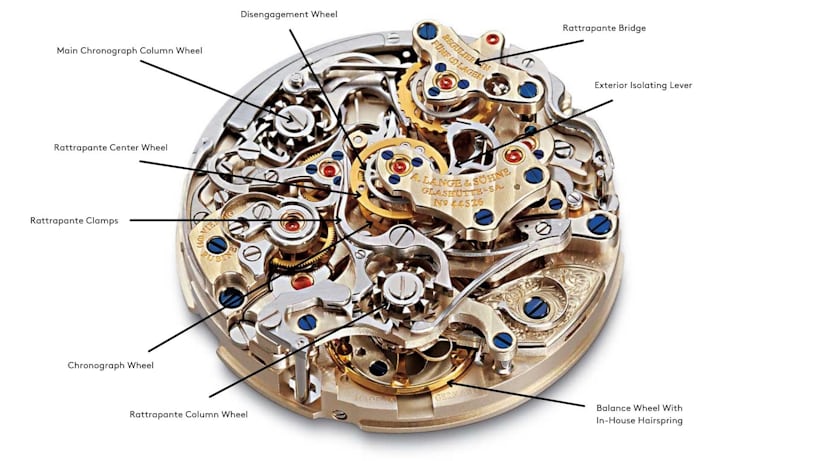

The movement inside the Double Split was eventually christened Calibre L001.1. This is no skinny splitter – Calibre L001.1 measures a thick 30.5mm × 9.5mm, runs in 3 Hz, with 38 hours of running autonomy, and is wound by hand. There’s also a pair of column wheels (one for the chronograph; one for the rattrapante mechanism), a flyback lever, a hand-engraved balance cock, and a lateral clutch. The minute hand jumps instantaneously, with no fault, for extra-precise timekeeping. Oh, and the original Double Split also included the first application of A. Lange & Söhne’s in-house hairsprings, a part of the company that we take for granted today but wasn’t always a part of its repertoire.

“We started developing the idea of making our own hairsprings around 1998-99,” says de Haas. “It was Mr. [Günter] Blümlein’s idea and a strategic decision. We were part of the LMH Group at the time, with IWC and Jaeger-LeCoultre, and if Lange could make hairsprings, it would make the LMH Group independent of Nivarox. Around 2002-03, we had the first hairsprings and put it in the first prototype of the Double Split.”

If you tried to find the in-house hairspring beating with the balance wheel in those initial prototypes, you’d be out of luck. The Calibre L001.1’s construction comprised three distinctive layers, blocking basically any view of the escapement in action. The movement is a beast, there’s no doubt about that, but all these layers are there for a reason – and that reason is energy.

“We had to create an isolating system which worked with the seconds counter, the stop-seconds hand, and the minutes counter – this was a big challenge for us,” explains de Haas. “Due to the isolating system we developed, there is no drop in amplitude at all. You pay the price in thickness, of course, but on the other hand, the movement is so impressive that even our team internally was like, ‘Wow.’ And maybe our colleagues in Switzerland were thinking, ‘Why didn’t we think of this? It’s so logical.'”

The isolating system A. Lange & Söhne created is the secret sauce for the success of both the Double Split and Triple Split. Today, it’s a patented design by the company, and it didn’t come easily.

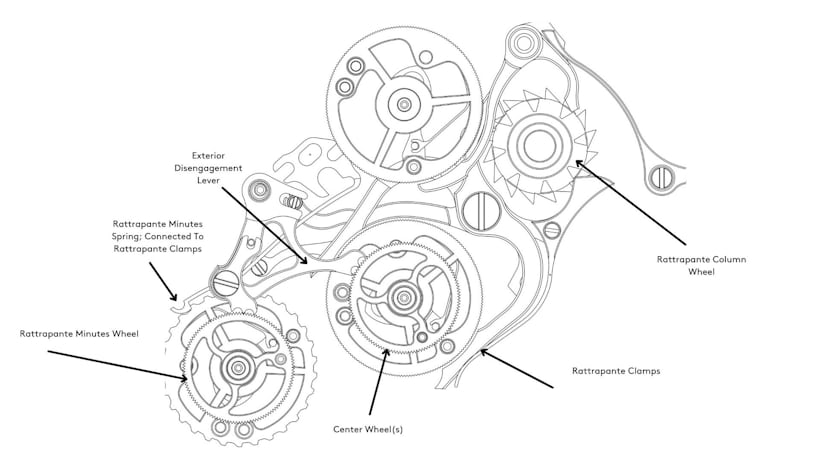

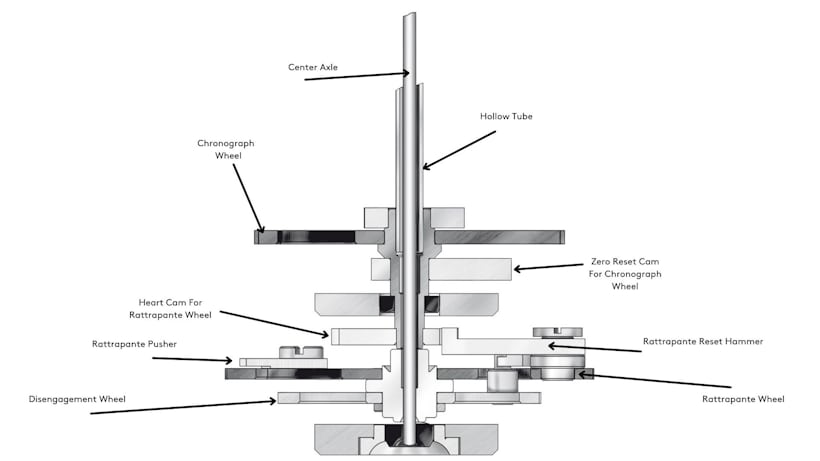

Let’s review the architecture of the Double Split. Consistent with basically every rattrapante chronograph out there, you’ll find a sandwich of gears in the middle of the movement. In the Calibre L001.1, it consists of a pair of extra-long, extra-thin hollow tubes, which act as axles for the chronograph center wheel and the rattrapante center wheel. These tubes cover the full extent of the movement, measuring almost 9mm in length, before connecting to the pinions for the co-axial central chronograph and rattrapante seconds hands on the dial.

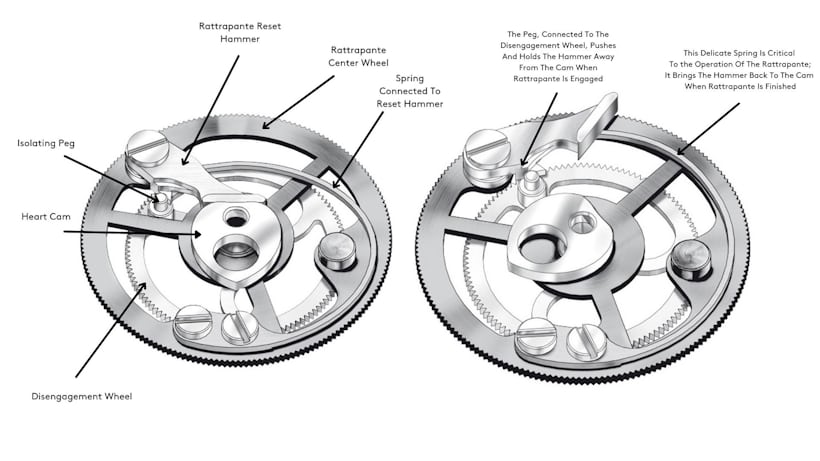

Inside the movement, a pair of heart-shaped cams are connected to the center wheels, individually, each equipped with spring-loaded levers/hammers that ensure the cams are positioned correctly along the hollow tubes to bind them together. These hammers act as zero-reset mechanisms on the chronograph center wheel, to return the chronograph seconds to the zero position, and to allow the rattrapante seconds hand to catch up to the chronograph seconds hand.

An isolating, or disengagement gear, is positioned underneath the rattrapante center wheel and connected to the rattrapante center axle (and the rattrapante seconds hand, itself). When the rattrapante mechanism is engaged, the clamps will immediately halt the rattrapante center wheel in its rotation – that’s how a rattrapante works – at the same time, the clamps trigger a larger isolating lever, positioned outside the central area, that pushes out the isolating gear, which uses an exterior peg to drag the rattrapante reset hammer connected to the heart-shaped cam with it; the outside isolating lever reaches the rattrapante minutes at the same time. The central seconds hand continues to rotate, and since it’s attached to the cam, the cam continues to rotate, as well. Concurrently, underneath the bridge at the top of the movement, a spring that’s connected to the rattrapante clamps pauses the rattrapante minute wheel in its rotation.

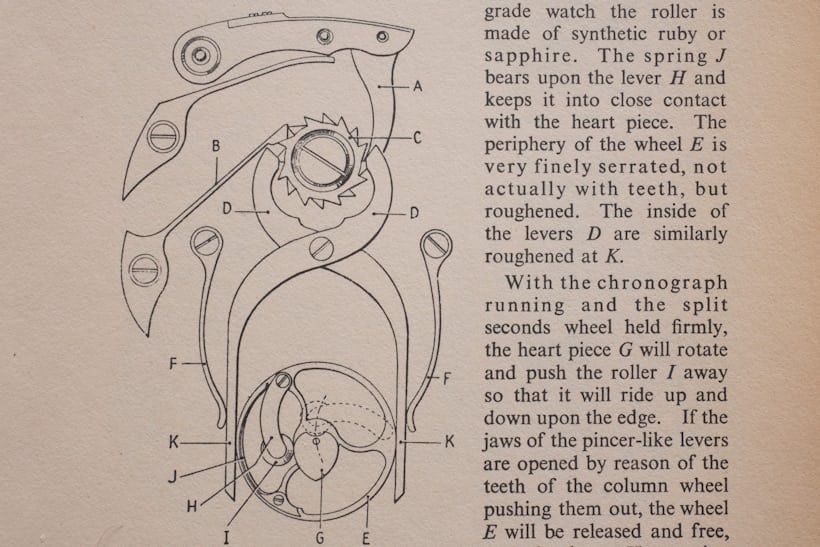

When a conventional rattrapante mechanism is engaged, a ruby roller connected to the low point of the heart-shaped cam is used to reduce friction rather than a separate isolating mechanism; however, this isn’t a complete fix. In this arrangement, when the rattrapante mechanism is engaged and the rattrapante center wheel is frozen by the clamps, the ruby roller rides up and down the sides of the still-rotating cam. While all this is happening, continued friction between the rattrapante cams and wheels inadvertently causes additional tension and resistance in the movement to build up, which eventually will negatively impact the movement’s amplitude and torque. When the rattrapante clamps are opened, the ruby roller jumps instantaneously, with the help of a small spring, to find the low point of the heart-shaped cam, in the process driving the split-seconds hand on the dial-side to catch up the chronograph seconds hand.

What makes the Double Split different is that when the rattrapante mechanism is engaged, it springs the isolating system into action. The connected rattrapante reset hammer is pushed and held away by a disengagement wheel located underneath the rattrapante center wheel, thus both the rattrapante heart-shaped cam and the chronograph wheel can continue to rotate without any pressure building up in the movement. When the rattrapante clamps are released, the larger isolating lever returns the smaller isolating gears to their original position, allowing the rattrapante levers to immediately spring back in position, searching for the notch on the heart-shaped cam and returning the rattrapante hands to their co-axial position, with the chronograph seconds and minutes hands.

“The trick was to find the right lever,” de Haas says. “Normally you have a rattrapante with center seconds and it’s quite easy, a lever comes in and pushes and stops things in the way. But it gets more complicated if you have to do that within the center, the stop seconds, and next to it, the minute counter. It’s one lever. Click. The lever design is able to isolate in the same movement with the center seconds lever, the rattrapante, and there’s also a lever on the minute counter, of course. It’s the same idea, of course. That’s the double split. And then the triple split is even more, because you have to do that with the hour counter.”

If the dual isolating mechanisms (for seconds and minutes) are the secret sauce to the Double Split’s success, it’s the hollow tubes running vertically through the Calibre L001.1 that anchor the idea in reality. These tubes are extremely delicate and measure less than 0.3mm in diameter in some areas, but they’re not so fragile that they can’t do their job as arbors and axles for the symphony of gears and wheels connected to them. Most chronographs have a single axle, connected to the chronograph wheel, on which the center chronograph seconds hand is mounted. A split-seconds chronograph of course has that axle, but it’s rendered as a hollow tube with an additional axle for the rattrapante placed inside.

“In the beginning, we didn’t know how to make these tubes,” says de Haas. “We asked a company that specializes in making injection needles, because they are very thin and hollow. But what we forgot is that it’s not important for an injection needle to be smooth inside because it contains liquid, while we had a little axle. Today we know how to make the tubes and the axles, and how to keep them smooth. The axles need to be perfectly straight; the thinner and longer they are, the more delicate it is to get it done.”

While the Double Split’s mechanics might have turned your mind to mush already, don’t forget it also incorporates a flyback function. Which, alongside the instantaneous jumping minute counter, cement the Double Split as one of the most impressive purpose-built mechanical tools for timekeeping available today. With a combination of rattrapante chronograph and flyback capability, it’s possible to measure elapsed time with the utmost precision, allowing you to measure split time and then reset that time in the blink of an eye.

“This is a time machine, a measuring machine,” says de Haas. “While the 1815 Rattrapante and Tourbograph are meant to celebrate traditional watchmaking, the Double and Triple split are about modern timekeeping and measurement.”

The Triple Split

If you look back now, you might think that creating the Triple Split was a foregone conclusion after the release of the Double Split in 2004. But that was not the case at all. In fact, A. Lange & Söhne didn’t even consider it until nearly a decade after the Double Split was released, when the A. Lange & Söhne Grand Complication made its debut in 2013.

“We really expected someone else in the industry to come up with an idea, to top our idea, but it never came,” says de Haas. “We finalized the Grand Complication and thought ‘Ah, why don’t we have a chronograph with an hour counter?’ So we started working on it. In 14 years, no one in the market reacted by creating something like the triple split. We were very surprised that no one had the idea.”

It took A. Lange & Söhne five years to develop the Triple Split, about the same amount of time required by the Double Split. The company’s goal was to bring in the split-hour display, without increasing the size of watch from the Double Split’s already ample proportions, while also increasing the power reserve from the modest 38 hours allowed by the Calibre L001.1.

Enter the manual-wind Calibre L132.1. It featured the same basic two horizontal counters, but introduced a stacked 12-hour register at 12 o’clock on the dial, pushing the power reserve display down to the six o’clock position. While it might be easy to think the Triple Split is a simple rehash of what A. Lange & Söhne did in the Double Split’s Calibre L001.1, except with a new layer added to the movement, that’s not what happened at all.

“It really is a new movement,” de Haas says. “Of course the basic gear train, the minute counter are the same, but the positioning of the movement is completely different. That was quite a tricky thing and not getting bigger – only 0.3mm bigger – is quite amazing since we now have 55 hours of power reserve and an extra function.”

The increase in power reserve was a formidable challenge that deserves its own deep dive – it’s really not as simple as you might expect it to be. What A. Lange & Söhne ended up doing was experimenting with one of the most sacrosanct sections of a movement: The balance wheel. It required adjusting the mass of the balance – not the size – so that it was lighter and required less energy to move, yet retained the same level of inertia. And because A. Lange & Söhne crafts their hairsprings in-house, they were able to adapt the hairspring used in the Calibre L132.1 to the lighter weight of the new balance wheel.

Some things didn’t change between the Double Split and Triple Split. The isolating mechanism works identically, while the hour register adopts the same shaft and axle system that’s used for the minutes and seconds displays. But now, the Calibre L132.1 consists of 556 components (!) and features a total of 10 (!!) hands on the dial. Another change worth calling out, after all the attention paid to the instantaneous jumping minute hand on the Double Split, is that the hour hands advance smoothly on the Triple Split.

One Split, Two Split, Three Split – Four?

Every example of the Double and Triple Split is assembled by just two watchmakers inside A. Lange & Söhne’s legendary Grand Complication workshop in Glashütte.

“We often talk about double assembly, but with these complications, it’s much more than double assembly,” de Haas says. “It’s like 40 times, 50 times. You put it together, adjust it, test it, dismantle it, adjust it again. Sometimes it takes two weeks, sometimes it takes three weeks.”

For instance, the original Triple Split, a limited edition of 100 watches cased in white gold, was launched in January 2018. The first pieces were delivered to clients nine months later, and the last of that run was delivered in January of this year. These watches, complicated as they are, take time to craft – and there is no expense spared in the creation process.

The Triple Split is, in fact, the most complicated chronograph currently available in A. Lange & Söhne’s deep catalog. It’s also a watch that I believe, along with its older sibling, best defines the company’s approach to watchmaking today – highly functional, technically groundbreaking, and deeply thoughtful.

So what’s next for A. Lange & Söhne?

The most recent addition to the Split family came at Watches & Wonders in April this year, with a new red gold option featuring a striking blue dial. But beyond that? What might a quadruple split even look like?

“We’re not working on a quadruple split, but we still have a lot of ideas – don’t worry,” de Haas says. “We’re working on 17 different movements at the same time right now. We have a five-year plan.”

Special thanks to Anthony de Haas and Jack Forster for once again helping me understand the intricacies of the rattrapante at A. Lange & Söhne.

Lead image, James @waitlisted. Triple Split, courtesy of @alangejourney.

Get More Articles Like This in Your Inbox

We're constantly creating great content like this. So, why not get it delivered directly to your inbox? By subscribing you agree to our Privacy Policy but you can unsubscribe at any time.